Agricultural work requires plant machinery which not only endures tough outdoor conditions, heavy during high use seasons. One of the many parts that keeps a farm machinery working is a pillow block bearing, allowing for support for rotating shafts while reducing friction in hundreds of applications. Choosing the right pillow block bearings manufacturer can mean the difference between a successful harvest and expensive downtime as they’re used in everything from combines & tractors to grain handling equipment & irrigation systems.

Understanding Agricultural Bearing Challenges

The agricultural setting is challenging to the proper function of standard industrial bearings. The fact that farm machinery is driven through dusty fields, exposed to moisture from irrigation and weather, subjected to temperature changes with the seasons and often run for long hours during planting and harvest time are all reasons this type of product needs exceptional attention. In addition, the agricultural equipment often loads return of load from empty implements to completely loaded grain carts resulting in dynamic stresses for bearing systems.

One caveat to bearing life in agricultural applications is the threat of dust and debris. It can allow fine contaminants to penetrate the bearing sealing surfaces, degrading lubrication and leading to abrasive wear on rollers and raceways. Additionally, moisture from morning dew, built-in irrigation systems or rainstorms can result in corrosion and early failure of a bearing when proper safeguards are not utilized.

Features To Look For In Agriculture Pillow Block Bearings

When choosing bearings for your farm equipment, there are a few key features to keep in mind. Reliable sealing solutions are at the top of the agenda, as they ensure an effective protection mechanism against infectious diseases. Search for bearings that has seal-type options, including metal and minimum seals allowing protection from dust or moisture without compromising performance of the bearing.

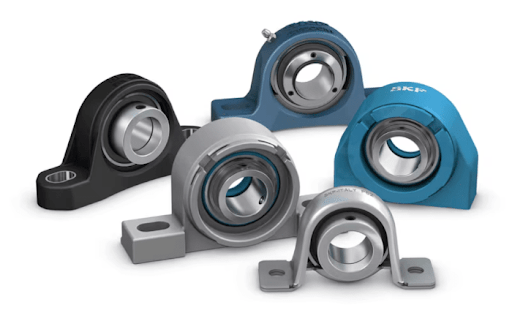

Similarly, housing construction has to be robust too. The cast iron body provides long life in rugged, demanding applications such as agricultural field equipment. Some manufacturers offer dedicated agricultural grade enclosures, featuring stiffened mounting points and thicker walls for the unique loads found in farm equipment. Stainless steel selections, although more costly, offer the best corrosion resistance to such aggressive environments and or when frequent decontamination is needed.

Look also at the lubrication qualities. Pillow block bearing with long or re-lubrication intervals are useful in many food and beverage applications. Grease fittings for easy maintenance, high-capacity grease reservoirs minimize time. Specialized grease formulations, are found in agricultural bearings provide better resistance to water washout and extreme temperatures prevalent in farming applications.

Load Capacity and Shaft Support

Bearings in agricultural machinery are generally subjected to load variations during service life. For instance, a header drive system of a combine harvester is stressed differently when harvesting a heavy crop than when only stubble remains. Such variation, etmakes it important to select bearings which have sufficient ii load capacity margins for during peak conditions and yet, still maintained reliable operation.

Remember to consider both radial and axial load demands when choosing a bearing. Agricultural applications often include belt-driven systems where high side loads can be generated, so bearings that can deal with combined loading conditions are essential. Shaft material and how the bearings are mounted also have bearing on bearing selection due to factors such as running accuracy, alignment, and mounting schemes which all effect proper bearing life in service and overall performance.

Environmental Protection Strategies

In addition to choosing bearings with appropriate environmental protection, the use of systematic protection techniques can do much to prolong bearing life in agricultural situations. Regular inspection rounds when servicing equipment, allow you to catch issues before they cause disruptions. Be particularly mindful of the seals, proper housing and contamination around the bearing areas.

Effective lubrication management goes beyond grease application. Knowing what you need for your operating conditions in terms of lubrication (temperature range, contamination level) helps to maximize bearing performance. There are some services that would greatly benefit from centralised lubrication systems which can give uniform flow directly to the lubricating point and cut down maintenance time.

Application-Specific Considerations

A variety of agricultural machinery feature specific bearing selection issues. Tillage implements work in high-dust, high-shock load applications for which bearings need to provide outstanding seal performance and integrity while being tough. Dust and differential operating speeds and loads of harvest equipment require bearings to be durable across a range of operating conditions.

Irrigation systems bring their own set of problems, being in constant contact with water and often remote making regular maintenance hard. In general, such applications require corrosion resistant materials and long grease intervals. Livestock machinery may contact washing and sanitizing chemicals, which demand bearings having excellent resistance to these chemicals as well as chemical resistant housing.

Cost-Effectiveness and Long-Term Value

Though premium certified-grade manufacturers of pillow block bearings may require a larger upfront cost, their many years usage when product and equipment maintenance costs are analyzed will probably make them an reasonable purchase. 5 Think through costs long-term When purchasing a VFD, it’s important to look at the true cost of ownership— purchase price, installation labor, maintenance and lost downtime. A broken bearing during harvest can mean downtime, and the difference between standard bearings price and premium options has never added up to loss of revenue in our book!

Standardizing on fewer bearing part numbers can result in cost savings via volume purchasing and lower inventory levels. Agricultural operations often find it advantageous to work with suppliers that can identify their individual requirements and provide bearings solutions that meet performance needs at a competitive price.

Maintenance and Monitoring

The performance of the bearing investment will be ensured only by establishing a suitable maintenance system. You should schedule maintenance according to hours of operation, time of the year and manufacturersuggestions rather than just following a calendar based interval. Record document performance and failure trends to opportunities for specification enhancements or maintenance streamlining.

Where practical, consider using monitoring of condition techniques. Common actions, such as paying attention to abnormal sounds and temperature levels during operation, while using shaft movement amount are cheap methods of looking out for potential problems before they lead to component failure.

Conclusion

From environmental concerns to load demands to application needs there are many factors you need to take into account when deciding which pillow block bearings are best suited for your agricultural machinery. By concentrating on strong sealing systems, correct housing materials and right Lubrication, agriculture customers can ensure downtime is kept to a minimum and equipment reliability is maximized. Investments in quality bearings made for the farming industry pays off with lower costs of maintenance, increased up-times and peace of mind during key working seasons.

The final key to success in agricultural bearing selection is to know your environment and select components that can withstand the task at hand. Through collaboration with knowledgeable suppliers and the tracking of detailed performance records, bearing selection can be continually improved in support of enhanced levels of equipment reliability and operational efficiency.